Production

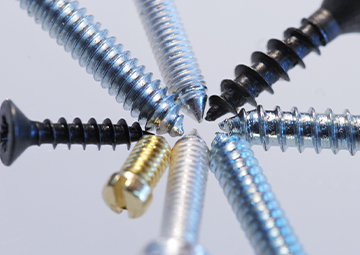

Screw production process

It is possible to produce both hot and cold formed screws, bolts and nuts. The first process, which is in fact the oldest, is used when creating material with large diameters, while the second one is reserved for small diameters and does not require extruding shavings during production, thus ensuring respect for the environment.

This production method offers several advantages, since the cold deformation of the material guarantees shapes as requested by the customer, including threading. One of such advantages concerns the structure of the screws or bolts produced. The deformed material fibers are not dispersed but follow the structure of the screw and give it greater resistance.

Visaf’s whole range of products is made at the company’s production sites. The production method is cold forming through presses, which ensures large quantities of product in a short time, namely over 150 million parts per month.

The production cycle is divided into five macro-areas: forming, milling, rolling, finishing and packaging.

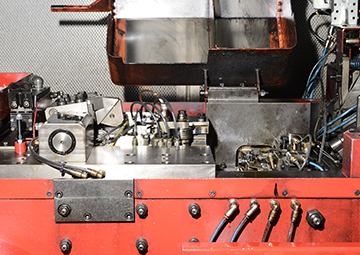

It is the most important production phase, since the careful processing of metals results into a rivet being generated from the coil.

This phase of the production cycle only occurs when producing a cut for the use of a screwdriver.